|

Distillation Columns : |

|

| |

|

|

We are Manufacturer, Supplier, Exporter of Distillation Columns, Batch Distillation Columns, Continuous Distillation Columns, Tray Column, Packed Column from Pune, Maharashtra, India

| We offer separation technologies with higher efficient multiple distillation column systems. Which operate at lower energy consumption with higher yield and consistent quality. |

| |

|

| Features : |

|

| |

• Multi product distillation systems

• Low energy consumption.

• State of art in plant automation

• Consistency in product quality

• Minimum shutdown |

| |

|

| |

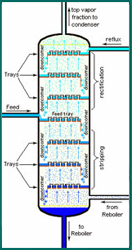

| Distillation is defined as a process in which a liquid or vapour mixture of two or more substances is separated into its component fractions of desired purity, by the application and removal of heat. |

| |

| Distillation column is a tall metal cylinder internally fitted with perforated horizontal plates used to promote separation of miscible liquids ascending in the cylinder as vapor. They also function to saparate air into its various components, principally oxygen and nitrogen. For separating air in distillation columns these are taken into their liquid form rather than gaseous state. |

| |

| Distillation columns are designed based on the boiling point properties of the components in the mixtures being separated. Thus the sizes, particularly the height, of distillation columns are determined by the vapour liquid equilibrium (VLE) data for the mixtures. |

|

| |

| |

Batch Distillation Columns : Batch Distillation Columns :

|

| |

| Batch Distillation Column is charged with a 'batch' and then the distillation process is carried out. When the desired task is achieved, a next batch of feed is introduced. A condenser to turns the vapors back to a liquid so they can be easily collected. Batch distillation comprises of tall column that is desirable to improve the separation. Finally, by using different collection vessels, the original mixture can be separated into fractions. Batch distillation is labor intensive |

| |

| |

Continuous Distillation Columns : Continuous Distillation Columns :

|

| |

| Continuous Distillation Columns process a continuous feed stream. No interruptions occur unless there is a problem with the column or surrounding process units. They are capable of handling high throughputs. A continuous column operates under steady conditions where the composition at a given location does not change over time. The composition only depends upon the position in the column and so additional product steams can be easily tapped at different heights and each tray will have a different composition of compounds. |

| |

| |

| The two major types of Continuous Columns are : |

| • Tray Column |

|

| Tray columns consist of physically separated pools of liquid which are in intimate contact with a vapor. |

| |

| • Packed Column |

| Packed columns are filled with a saddle shaped packing. This packing provides a lot of surface area for the vapor to condense upon and assures that the liquid and vapor are in intimate contact |

|

| |

|

| |

|

| |

|

|

|